FEEDING DEVICES

Contact us for help?

Contact with us through our representative or submit a business inquiry online.

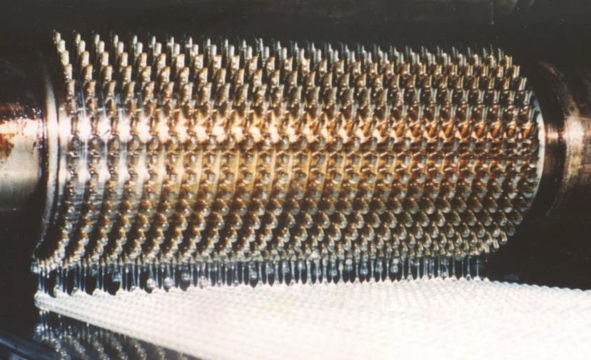

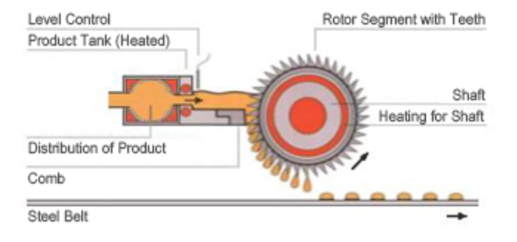

Rolldrop® Pastillator

Main advantages

- Suitable for steel belt coolers up to 2000 mm width

- Open construction for easier cleaning and maintenance

- Low product retention time on heated area to avoid any product degradation

- Application versatility for medium and low viscosity products

- Size of the pastilles is related to the tooth dimensions

- Continuous production of regular drops without powder and fines

The rotational speed of the Rolldrop® is synchronized with the speed of the cooling belt in order to have well shaped pastilles

Products treated with Rolldrop®

- Waxes

- Polyethylene waxes

- Hydrocarbon resins

- Fatty alcohols

- Fatty acids

- Fatty amines

- EVA hot melt adhesives

- Acrylic resins

- Phenolic resins

- Colophony resins

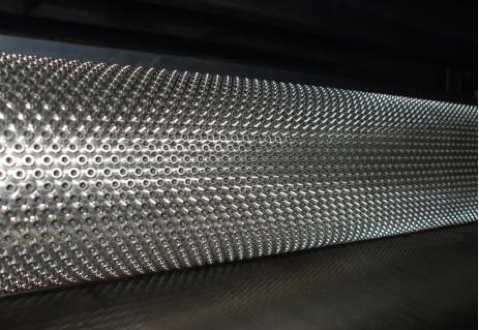

Accudrop® Pastillator

Main advantages

- No need for a “re-feed” to clean the shell

- Thicker pastilles, providing higher production rates

- Less product build-up on the shell, providing cleaner operativity

- AccuDrop® application versatility for medium and low viscosity products

- The rotational speed of the AccuDrop® is synchronizedwith the speed of the cooling belt, in order to have well shaped pastilles

Experienced Products with Accudrop®

- Sulphur (elemental)

- Sulphur bentonite

- Sulphur based fertilizer

- Caprolactam

- Paraffin

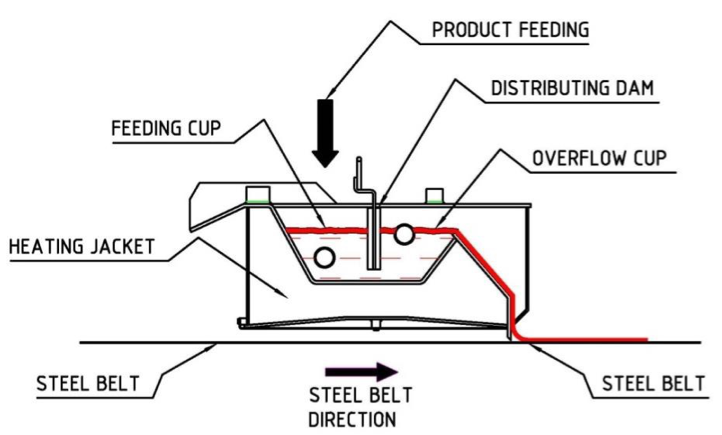

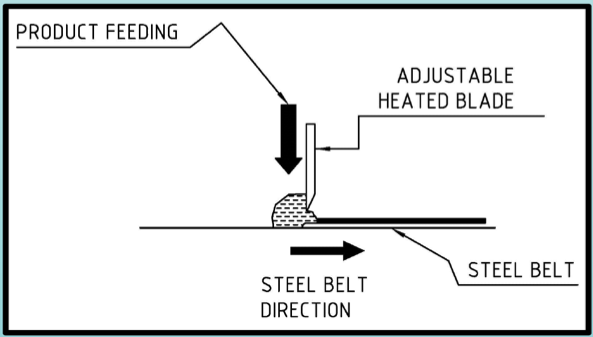

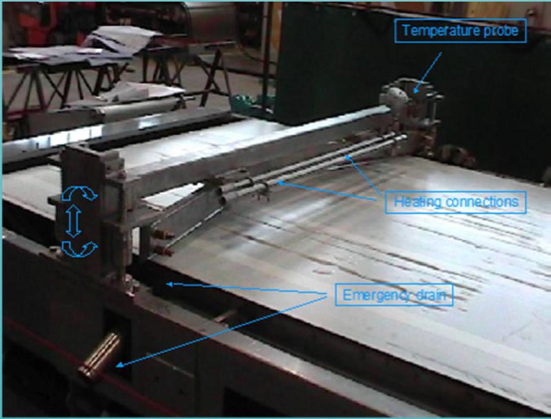

Weir Feeder

Ribbon Former®

The weir feeder is suitable to feed alayer of very liquid products that arenot infected by the presence of air.Our feeders are available for allwidths of belts and can be placed onexisting belt machines too.Pivoting system including pneumaticlifting device, for easy cups cleaning,are available under request.

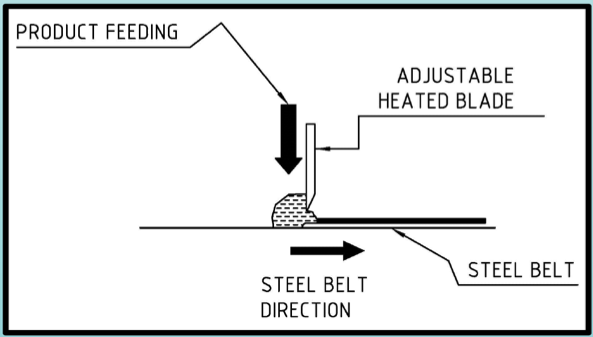

The weir feeder’s functional scheme isreported sideways:

Main advantages

- The opening of the gate is adjustable by means of a hand wheel; a full automatic system is available under request.

- The external sides of the feeder can be easily removed for cleaning.

- The ribbon former is suitable to feed medium-high viscosity products that are sensitive to air.

- Our feeding system is available for all widths of belts and can be placed on existing belt machines too.

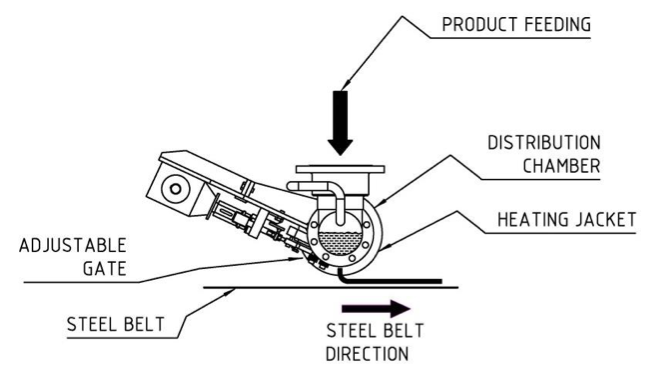

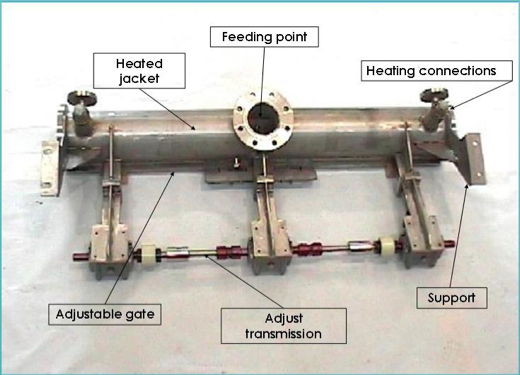

Casting device

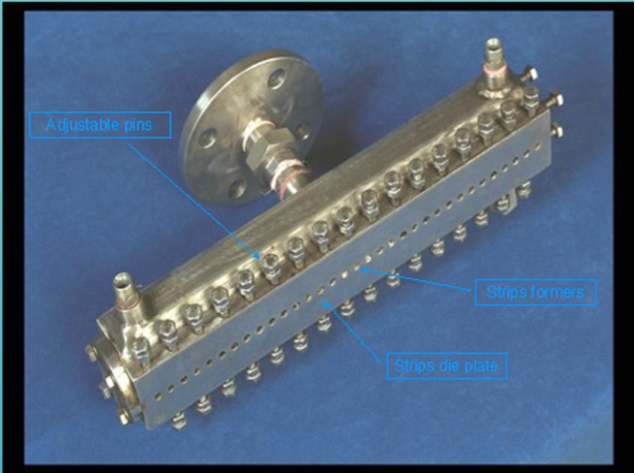

Strips former

The strips former is suitable to feed strips on belts fora wide range of products.

The flow of the material is distributed by aninternalchamber; the chamber can be easily cleaned orinspected by means of the two openable flangeslocated in the external limits of the chamber.The adjustable pins can regulate the output of theproduct from the holes of the die.