SERVICE STELL BELTS

Contact us for help?

Contact with us through our representative or submit a business inquiry online.

SERVICE STEEL BELTS

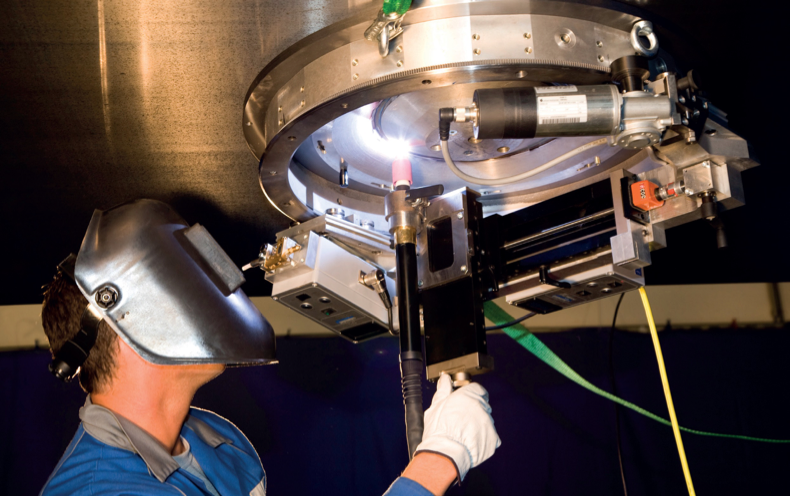

bernfixx® service from Berndorf

Continuous service In order to ensure the productivity of customers, the Berndorf Band Group offers extensive services as well as pioneering service equipment and devices centered around the steel belt as part of their bernfixx® quality brand. Operating world-wide, the company’s service network performs such tasks as steel belt installations, repairs, inspections, maintenance and training for all types of belts.

A complete range of after-sales services, frequent development of new steel belt repair methods, maintenance tools and working techniques as well as a broad offer for steel belt users to get their maintenance specialists trained in the latest technologies give proof of the outstanding care of our customers

Comprehensive technical customer service, development of special tools and a wide range of training courses all ensure that our customers receive the very best support. All services, service tools and trainings are offered under the family brand bernfixx®.

This brand stands for top quality and reliability.

Berndorf Band has an international service network offering steel belt installation, repair and inspection, all under the technical direction of its service centre in Berndorf. Endless, open, polished and ground belts are installed, as well as belts with v-ropes or retaining strips, in every available material and dimension.

A wide variety of service activities are offered, from emergency repair to preventive maintenance agreements.

A team of service specialists located here in the Thailand in addition with a team of engineers in Berndorf Band and further afield worldwide ensure expert advice and scheduled installation and maintenance works from each and every team member.

All service specialists are Berndorf accredited and receive continuous and ongoing training & support to ensure that the quality of all our works meet with the customer expectations as well as our high standards

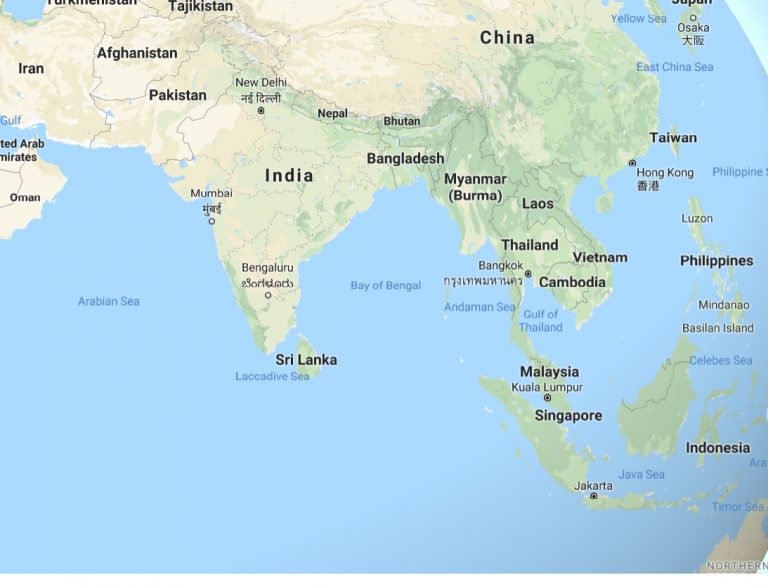

Service Areas

We are service hub of Berndorf Band Group for South East Asia (Thailand, Malaysia, Singapore, Indonesia, Vietnam, Philippines, Laos, Myanmar,) and Pakistan, Sri Lanka, Bangladesh, Bhutan also our service area.

Service offering

- Steel belt installation

- Steel belt replacement

- Steel belt inspection

- Steel belt repair ( crack, dent, deformation and etc..)

- Shot peening

- V-rope repair

- Training

Service equipment from Berndorf

- Magnetic clamping device

- Patching Tool

- Mechanical clamping device

- Belt edge maintenance and repair tool

- Hot bonding device

- High power shot peener

- Repair kit

- Cutting and welding device

Belt Damages

Dents, Small Deformation

What is a dent

A dent is a local flatness deviation which either goes inside or outside and which does not snap outside or inside during the running of the belt or during external stress.

How does a dent happen?

The reasons for a dent are external forces which work from the outside or Inside onto the belt and which deform the belt material plastically.

MEASURING METHODS

Which measuring instruments are necessary a dent exactly ?

– meter or sliding caliper for determination of the size and the position

– precision ruler (75 mm or 200 mm long ) and feeler gauge (0.05 mm- 1 mm) for measuring the height (or depth)

REASON OF BELT DAMAGE

A small screw falls between the belt and the drum or into the mat. Glue balls and mat forming defects.

PREVENTVE STEP

Optimal mat forming (no glue balls, not mat doubling)

Check the scraper (to be in touch over the whole belt width and being Cleaned periodically).

Use a cleaning brush (also to be in touch over the whole belt width).

Install electro magnets in order to identify metal the mat.

Check brake layers

POSSIBLE RISK IF DAMAGE WILL NOT BE REPAIRED

Cracks will occur (maybe no single crack, so maybe a patch is needed)

POSSIBLE REPAIR METHODS AND TOLERANCES

Depending on the kind of deformation:

– flattening with the hammer

– shrinking method

– insert of patch by hand or Berndorf patching tool

NECESSARY TOOLS

Flattening hammer or standard repair tools and patching tool

Cracks

What is a crack.

A crack is a local fracture. In most causes it is caused by overstress

– Single cracks

– A lot of cracks close to each other

MEASURING METHODS

Length of crack / visible on both sides ? Are deformations visible near the crack ?

REASON OF BELT DAMAGE

Belt edge touches machine frame –if edge cracks

Foreign particle between belts or between belt and drum which and too big material defect

Bad welding, Material fatigue .

PREVENTIVE STEP

Belt inspection from time to time (every 2 weeks ). Especially the edges

POSSIBLE RISK IF DAMAGE WILL NOT BE REPAIRED

The belt splinter / production stop

POSSIBLE REPAIR METHODS AND TOLERANCES

– Single cracks can be welded

– A lot of cracks very close to each: insert pieces like round Patches or trapeze.

NECESSARY TOOLS

– Berndorf Standard repair tools

– Berndorf Patching tools